In industries where metal plays a central role—from automotive and manufacturing to shipbuilding and construction—rust is a relentless enemy. It weakens structures, destroys aesthetics, and reduces functionality. Traditional rust removal methods often fall short in precision, cleanliness, and sustainability. This is where a handheld laser rust remover steps into the spotlight.

This article explores everything you need to know about this powerful tool: how it works, who uses it, and why it’s becoming the go-to method for rust removal in both professional and industrial environments.

Understanding the Core of Laser Rust Removal

A handheld laser rust remover operates using a high-intensity beam of light, focused on rusted metal surfaces. When the laser beam contacts the surface, it heats the rust and contaminants rapidly. This causes them to vaporize or separate from the substrate without damaging the metal underneath. The result is a clean, bare-metal surface that’s ready for further processing or protection.

This process is called laser ablation, and it’s fast, dry, non-contact, and leaves no residue behind. It eliminates the need for chemicals, abrasives, or water-based cleaning agents. Because it’s a targeted method, it minimizes waste and maximizes efficiency.

Who Can Benefit from a Handheld Laser Rust Remover?

While handheld laser rust removers were once considered tools for advanced industrial use only, they are now finding their way into smaller workshops, garages, restoration labs, and even among individual metalworkers. Here’s a glimpse into who is integrating these tools into their operations:

-

Automotive Restoration Experts: Removing rust from old car frames, underbodies, and mechanical components without damaging original parts.

-

Shipyards and Marine Technicians: Eliminating rust from ship hulls, anchors, and metal decking where salt exposure is high.

-

Industrial Maintenance Crews: Keeping machinery rust-free in oil & gas, mining, and heavy equipment sectors.

-

Artists and Metal Crafters: Cleaning used or recycled metal parts without sandblasting or grinding.

-

Facility Managers: Removing surface contaminants from pipes, railings, and architectural installations.

The Technology Behind Handheld Laser Rust Removers

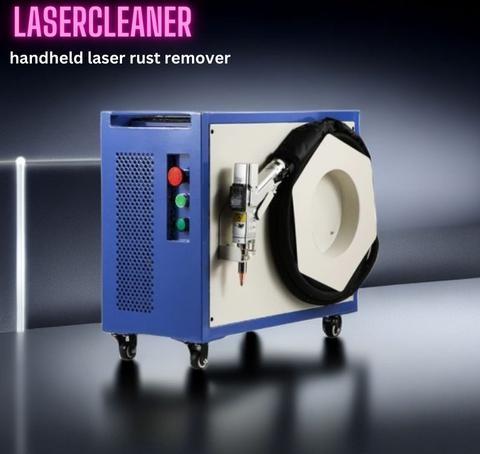

The handheld laser rust remover typically comes with a compact laser gun connected to a laser source. Most devices use fiber laser technology, known for its durability, energy efficiency, and minimal maintenance. The gun is designed for ergonomic use and can be operated for long hours with minimal fatigue.

Laser settings can be adjusted to match the thickness and type of rust being removed. Some models also feature pulse-width modulation, which allows more refined cleaning of delicate surfaces. Cooling systems (often air or water-based) ensure the device remains operational over long periods.

The laser beam removes rust in two primary modes:

-

Continuous Wave (CW): For deeper corrosion layers and fast cleaning.

-

Pulsed Mode: For precision cleaning of thin rust without damaging underlying materials.

Why Is the Handheld Laser Rust Remover a Game Changer?

Because the process is dry, precise, and clean, industries no longer have to depend on messy sandblasting, harmful solvents, or mechanical grinding that may compromise the metal structure. With a handheld laser rust remover, work becomes faster, safer, and more controlled.

Imagine trying to clean intricate engine parts or heritage metalwork. Sandblasting would be too harsh, and chemicals may damage the material. A laser system allows operators to adjust focus and intensity, offering the freedom to clean only the rust—nothing more, nothing less.

Operational Use: How to Use a Handheld Laser Rust Remover

Operating a handheld laser rust remover involves several steps to ensure both safety and efficiency. Here's what a typical workflow looks like:

-

Preparation:

-

Ensure the work area is well-ventilated.

-

Wear safety gear, including laser-protective goggles, gloves, and protective clothing.

-

Check for reflective surfaces around the work zone to avoid accidental laser reflection.

-

-

Machine Setup:

-

Connect the laser head to its power source.

-

Choose settings based on surface conditions: wattage, pulse duration, and focus distance.

-

-

Laser Cleaning:

-

Hold the gun steady and direct the beam over the rusted area.

-

Keep a consistent pace—too slow may overheat the metal, too fast may leave rust behind.

-

Repeat if necessary for deeper corrosion layers.

-

-

Post-Cleaning:

-

Inspect the surface to ensure complete rust removal.

-

Apply primer or anti-corrosion coating if required.

-

Clean the laser lens and store the equipment safely.

-

The learning curve is minimal. Operators typically become proficient within a few hours of training.

Cost and Accessibility

A major concern for many buyers is pricing. The cost of a handheld laser rust remover ranges from $3,000 to $15,000, depending on wattage, cooling system, brand, and country of origin. Lower-wattage models (20W–50W) are great for light rust and smaller parts, while industrial-grade units (100W–2000W) are suited for heavy-duty applications.

Although the upfront investment may seem high, long-term savings from reduced labor, no consumables, and less maintenance often outweigh the initial cost.

In addition, many suppliers now offer leasing, rent-to-own, and monthly installment options. This opens the door for small businesses and independent workers to access professional-grade equipment without heavy financial burden.

Safety First

Because it involves high-powered lasers, safety is paramount. All operators should follow laser safety standards, including:

-

Using certified laser protective eyewear

-

Ensuring only trained personnel are allowed in the operation zone

-

Installing proper ventilation or smoke extraction systems to handle vaporized materials

-

Placing warning signs around active zones

-

Avoiding use near reflective surfaces

Regulations vary by country, so it's important to follow local compliance for Class 4 laser equipment.

Maintenance and Durability

The handheld laser rust remover is built to last. Most models offer up to 100,000 hours of operational lifespan thanks to fiber laser technology. Maintenance is minimal—mostly limited to cleaning the lens and checking for debris or blockages.

Because there are no moving parts in the beam generation process, the chance of mechanical failure is low. This reliability is another reason why more industries are turning to laser-based rust removal over traditional methods.

Where to Buy and What to Look For

When choosing a handheld laser rust remover, it’s essential to consider:

-

Laser Power: Choose based on your intended application.

-

Cooling Type: Air cooling is more portable; water cooling offers better heat management for long sessions.

-

Portability: A lighter laser gun and wheeled console offer ease of movement.

-

User Interface: Touchscreen controls and preset modes make operations smoother.

-

Warranty and Support: Go for brands with local technical support and at least a 1-year warranty.

Popular brands include:

-

JPT

-

Raycus

-

MaxPhotonics

-

IPG Photonics

You can buy them directly from manufacturers, authorized distributors, or eCommerce platforms that specialize in industrial tools.

Final Thoughts

The handheld laser rust remover is not just a tool—it’s a shift in how we approach metal surface cleaning. From automotive garages to heavy industry, this technology is making rust removal more efficient, safer, and cost-effective.

Whether you're reviving classic cars, maintaining marine equipment, or restoring metal artifacts, this laser solution offers an unparalleled level of control and precision. Its rise in popularity is well deserved, and it's only a matter of time before it becomes standard in workshops and factories around the world.