In an increasingly digital and automated world, the boundaries between mechanical, electrical, and software engineering are becoming blurred. At the heart of this technological evolution lies mechatronic design—a multidisciplinary engineering approach that combines mechanical engineering, electronics, computer control, and systems thinking into the design of intelligent products and processes.

Mechatronic systems are present in nearly every modern innovation, from industrial robots and autonomous vehicles to smart home appliances and medical devices. As technology becomes more integrated and intelligent, mechatronic design is essential to building systems that are efficient, reliable, and responsive.

What is Mechatronic Design?

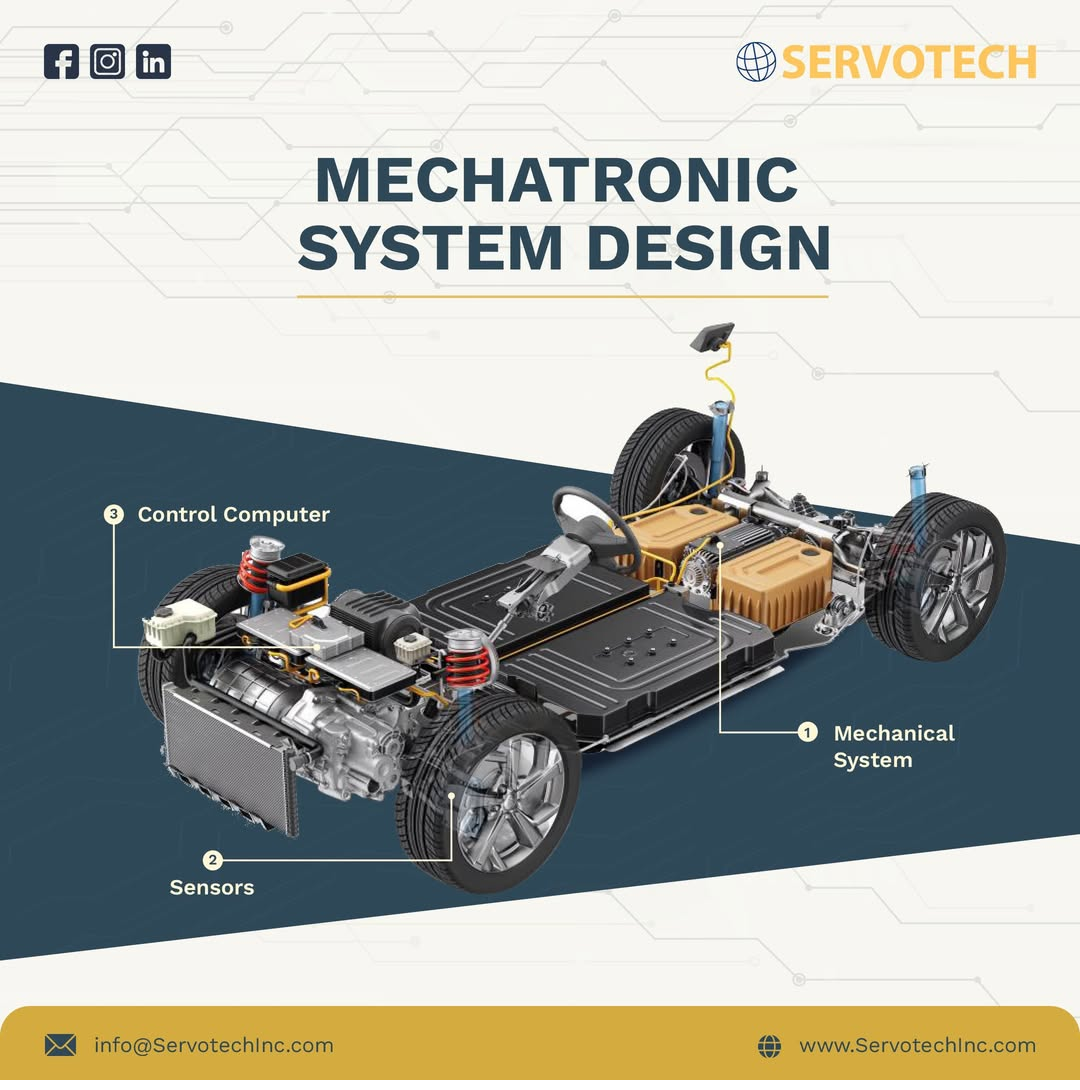

Mechatronic design refers to the integrated development of systems that include mechanical components, electronics, sensors, actuators, and control software. Rather than designing these subsystems separately, engineers work collaboratively across disciplines from the early stages of product development.

The primary objective of mechatronic design is to create simpler, smarter, and more functional systems. This approach reduces system complexity, shortens development cycles, and improves performance through synergy between disciplines.

Core Components of Mechatronic Design

- Mechanical Systems: These include the physical structure, actuators, gears, and linkages. The mechanical part is responsible for motion, force, and structure.

- Electronics: Mechatronic systems rely on electronic components such as microcontrollers, sensors, power supplies, and interface circuits to interpret signals and control actions.

- Control Systems: Software algorithms are used to process sensor inputs and generate appropriate control outputs, often using real-time feedback systems.

- Computer Engineering: Embedded systems and software logic bring intelligence to the mechatronic system, allowing it to perform tasks autonomously or with minimal user input.

- Sensors and Actuators: Sensors collect real-world data (temperature, pressure, position, etc.), while actuators carry out physical tasks based on the control logic.

Applications of Mechatronic Design

The influence of mechatronic design spans across multiple sectors:

- Automotive Industry: Features such as adaptive cruise control, automatic braking systems, and electric power steering rely heavily on mechatronic systems.

- Manufacturing and Robotics: Automated assembly lines, industrial robots, and CNC machines are classic examples of mechatronic systems enhancing productivity.

- Healthcare: Advanced prosthetics, robotic surgery tools, and diagnostic equipment combine mechanical precision with electronic intelligence.

- Consumer Electronics: Devices like smart washing machines, cameras with auto-focus, and drones are powered by mechatronic principles.

- Aerospace: Fly-by-wire control systems, UAVs (unmanned aerial vehicles), and satellite positioning mechanisms are sophisticated mechatronic systems.

Benefits of Mechatronic Design

- Improved Performance and Efficiency

By integrating components from multiple domains, mechatronic systems can optimize operations, reduce energy consumption, and enhance functionality. - Compact and Lightweight Solutions

Through smarter integration, systems become more compact, minimizing the number of components and reducing weight—a crucial factor in automotive and aerospace industries. - Enhanced Reliability

Close collaboration across disciplines reduces the risk of design flaws, ensuring that the final product functions as intended across multiple domains. - Faster Time-to-Market

Concurrent engineering approaches used in mechatronic design shorten development cycles, allowing businesses to respond quickly to market demands. - Easier Maintenance and Diagnostics

Intelligent systems can monitor their own health and predict failures, reducing downtime and improving serviceability.

Mechatronic Design Process

A successful mechatronic design involves several key stages:

1. Requirements Analysis

Define what the system is supposed to do, under what conditions, and within what constraints. Requirements are gathered from stakeholders and translated into functional specifications.

2. Conceptual Design

High-level architectures are created, showing how mechanical, electrical, and control components will interact. Trade-off studies help identify optimal solutions.

3. Modeling and Simulation

Virtual models are developed to simulate system behavior before physical prototypes are built. This reduces costs and identifies performance issues early.

4. System Integration

Mechanical parts, electronic circuits, sensors, and software are integrated into a working prototype. Integration requires careful planning and thorough testing.

5. Testing and Validation

Testing ensures that the system meets performance standards and behaves reliably under real-world conditions. Validation confirms the design satisfies user requirements.

6. Deployment and Maintenance

The final product is deployed, and systems are put in place for monitoring, diagnostics, and updates as needed.

Tools and Technologies Used

Mechatronic design uses a range of engineering software and tools, including:

- CAD (Computer-Aided Design): For mechanical part modeling.

- MATLAB/Simulink: For system simulation and control algorithm development.

- C/C++ and Python: For embedded software development.

- LabVIEW: For test automation and data acquisition.

- PLC Programming: For industrial control systems.

Integration platforms like Model-Based Design and Digital Twins further support mechatronic development by enabling real-time simulation and lifecycle management.

Challenges in Mechatronic Design

Despite its many advantages, mechatronic design faces challenges:

- Interdisciplinary Collaboration: Effective communication between mechanical, electrical, and software teams is critical and sometimes difficult.

- Complexity Management: Integrating multiple systems requires careful planning to avoid cascading failures or unanticipated interactions.

- Cost and Time Constraints: Advanced technologies and tools can be expensive, and ensuring timely development within budget is a constant pressure.

- Cybersecurity: Intelligent systems with network connectivity can be vulnerable to cyber-attacks and must be designed with robust security features.

The Future of Mechatronic Design

With the rise of Industry 4.0, the Internet of Things (IoT), and Artificial Intelligence (AI), the role of mechatronic design will become even more pivotal. Intelligent, connected, and autonomous systems will dominate the future landscape, and mechatronics will provide the foundation for their development.

Areas like autonomous robotics, wearable technology, and smart manufacturing systems are expected to grow rapidly, demanding highly skilled mechatronic engineers and advanced design strategies.

Conclusion

Mechatronic design by Servotechinc represents the future of engineering—where integration, intelligence, and innovation come together. By breaking down silos between disciplines and embracing a systems-thinking approach, mechatronic design enables the development of smarter, more efficient, and more adaptable technologies.

Whether it’s revolutionizing the way we drive, manufacture, heal, or live, mechatronics is not just a design methodology—it's a technological movement that continues to transform the modern world.