In the growing industrial landscape of Joliet, Illinois, the demand for high-performance process controls systems is on the rise. As manufacturers, utilities, and other industrial sectors look to streamline operations and enhance accuracy, the importance of advanced automation and control technologies becomes paramount.

From chemical plants to food processing facilities, process controls systems help monitor, manage, and regulate critical variables across a wide range of processes. These systems not only boost efficiency but also increase reliability, reduce human error, and support long-term operational growth.

What Are Process Controls Systems?

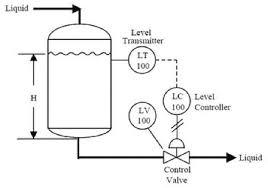

Process controls systems are integrated networks of hardware and software that automatically regulate variables such as temperature, pressure, flow rate, and chemical composition. These systems ensure a consistent output by controlling internal processes through continuous monitoring and feedback loops.

The main components of a typical process control system include:

-

Sensors and transmitters for data collection

-

Actuators and valves to enforce changes

-

Human-Machine Interfaces (HMI) for user interaction

These components work together to create automated workflows that can respond to changes in real time, enhancing both performance and safety.

Why Joliet Industries Need Process Controls Systems

Joliet is home to a variety of industrial operations—from manufacturing and logistics to energy and water management. To stay competitive and efficient, these sectors require advanced control solutions tailored to their unique process needs.

🔧 Advantages of Implementing Process Controls Systems

-

Improved Production Efficiency: Streamlining operations reduces downtime and enhances throughput.

-

Energy and Cost Savings: Automated control reduces waste and optimizes resource usage.

-

Quality Assurance: Consistent control over variables ensures uniform product output.

-

Regulatory Compliance: Systems can log and report data needed for safety and environmental audits.

-

Enhanced Safety: Real-time alerts and interlocks prevent dangerous operating conditions.

Industries in Joliet That Benefit from Control Systems

🏭 Manufacturing and Assembly

Whether it’s automotive, metal fabrication, or packaging, manufacturing facilities in Joliet depend on process control systems for equipment synchronization, quality control, and high-speed production.

🚰 Water and Wastewater Treatment

Municipal facilities in Joliet rely on automation to regulate flow rates, monitor chemical dosing, and ensure clean water supply while adhering to state and federal regulations.

🧪 Chemical and Petrochemical Plants

Controlling chemical reactions with precision is essential for product quality and safety. Process control systems manage variables like flow rates, pressure, and mixing ratios.

🌾 Food & Beverage Processing

From temperature-sensitive production lines to sanitation protocols, the food industry uses control systems to maintain safety, compliance, and consistent taste profiles.

Key Technologies Driving Process Control in Joliet

The future of industrial performance lies in automation. Businesses in Joliet adopting cutting-edge control technologies are not only improving today’s operations but are also preparing for long-term scalability.

🧠 Programmable Logic Controllers (PLCs)

PLCs are central to process automation. They execute logic-based commands, manage real-time input/output signals, and are ideal for repetitive tasks and safety-critical operations.

📊 SCADA Systems (Supervisory Control and Data Acquisition)

SCADA platforms allow operators in Joliet to monitor and manage complex systems remotely. Data logging, trend visualization, and alarms improve decision-making and system responsiveness.

🖥️ HMI (Human-Machine Interface)

Operators access vital process information and manual controls through graphical interfaces, making complex systems more intuitive and manageable.

🌐 Industrial IoT and Cloud Integration

Advanced process controls are increasingly connected to cloud platforms, enabling remote diagnostics, predictive maintenance, and performance analytics.

Steps in Designing and Implementing Process Controls Systems

-

Needs Assessment and Site Evaluation

Identify the specific process requirements, current inefficiencies, and future scalability needs. -

System Architecture Design

Define hardware, software, communication protocols, and safety systems appropriate for the application. -

Programming and Configuration

Develop logic programs, interface screens, and alarm systems suited to operational goals. -

Installation and Integration

Ensure proper sensor placement, wiring, and communication network setup. -

Testing and Commissioning

Validate the system under real-world conditions, calibrate components, and resolve startup issues. -

Training and Documentation

Equip plant personnel with knowledge to operate and maintain the system efficiently. -

Ongoing Maintenance and Upgrades

Implement remote support, regular system audits, and software updates to maintain peak performance.

Current Trends in Process Control Systems

Joliet’s forward-thinking businesses are embracing these innovations in process automation:

🔍 Predictive Analytics & AI

Advanced algorithms analyze trends to predict component failure or process anomalies before they cause downtime.

⚙️ Edge Computing

Processing data locally (on-site) reduces latency and allows faster real-time decisions in sensitive processes.

🧩 Modular and Scalable Designs

Modern systems support future expansion, allowing plants to grow without major overhauls.

🔐 Enhanced Cybersecurity

As systems become more connected, protecting control networks from digital threats is a top priority.

The Economic Value of Control Systems in Joliet

With its proximity to major industrial corridors and transportation networks, Joliet is a growing hub for manufacturing and logistics. To remain competitive, companies must adopt technologies that enhance precision and reduce manual intervention.

Process controls systems are not just operational tools—they’re strategic investments that improve ROI, reduce unplanned downtime, and support consistent product quality. As industrial regulations and consumer demands evolve, robust control infrastructure will be essential for sustained success.

Final Thoughts

In a competitive industrial environment like Joliet, Illinois, implementing reliable process controls systems is crucial for driving operational efficiency, safety, and growth. From design and configuration to ongoing support, selecting the right control solutions ensures that your business runs smoothly and profitably.

For industries in Joliet seeking professional-grade automation services, Xtreme Automation LLC delivers customized process control solutions tailored to your unique needs and industry standards.