In today's technology-driven world, effective thermal management is crucial for the performance, reliability, and longevity of electronic devices. One of the most innovative and efficient solutions in this field is the skived heatsink. As electronic devices continue to shrink while their power output increases, the demand for compact yet highly efficient cooling solutions has grown exponentially. Skived heatsinks have emerged as a top choice across various industries due to their superior thermal performance and cost-effectiveness.

What is a Skived Heatsink?

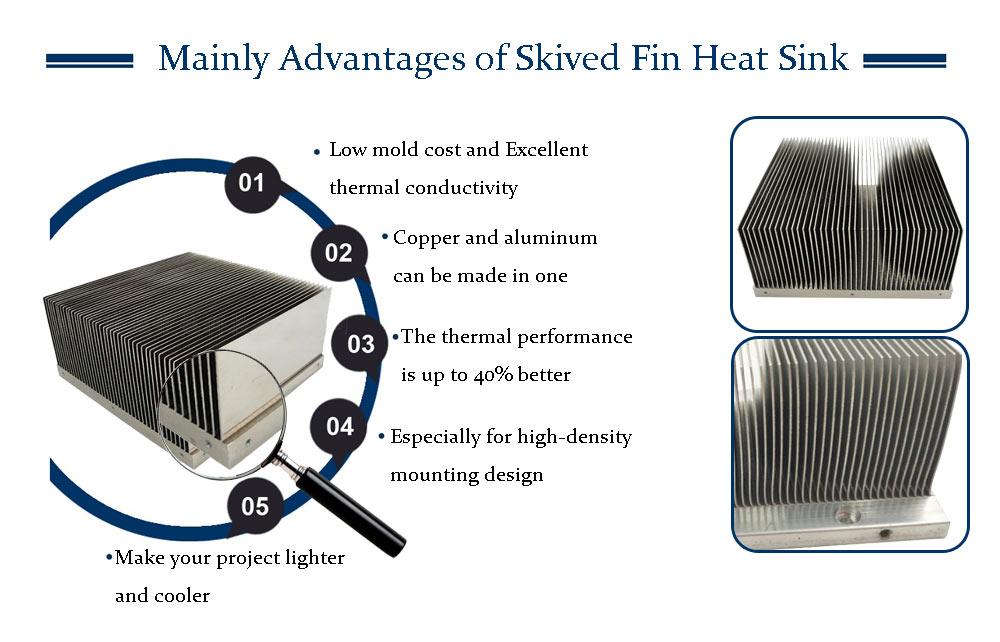

A skived heatsink is a type of heat dissipation component manufactured through a process called skiving. In this method, a single block of metal—typically copper or aluminum—is cut with a specialized blade to create thin, closely spaced fins. These fins remain attached to the base, forming a monolithic structure without any welding or soldering. This results in excellent thermal conductivity between the base and fins, enabling efficient heat transfer.

Unlike traditional extruded or bonded heatsinks, skived heatsinks offer more design flexibility, finer fin structures, and better performance in limited space. Their unique manufacturing process makes them ideal for applications requiring high thermal efficiency in compact formats.

Advantages of Skived Heatsinks

-

Superior Thermal Conductivity

One of the primary advantages of skived heatsinks is their excellent thermal conductivity. Because the fins are part of the same metal block as the base, there is minimal thermal resistance between the two. This direct contact ensures that heat is quickly transferred from the base to the fins, where it can dissipate more efficiently. -

High Fin Density

The skiving process allows for a much higher fin density compared to other manufacturing methods. More fins mean more surface area, which translates to better heat dissipation. This makes skived heatsinks particularly effective in scenarios with limited airflow or space constraints. -

Material Versatility

Skived heatsinks can be manufactured using various metals, most commonly aluminum and copper. Aluminum is lightweight and cost-effective, while copper offers superior thermal conductivity. The choice of material depends on the specific requirements of the application. -

Cost-Effective for Medium Volumes

While not always the cheapest option for very high-volume production, skived heatsinks strike a perfect balance between performance and cost for medium-volume applications. The elimination of additional joining processes such as welding or soldering also reduces production complexity and potential points of failure. -

Customizable Designs

Skiving technology allows for highly customizable heatsink designs. Engineers can adjust fin height, spacing, and thickness to optimize thermal performance for specific applications. This makes skived heatsinks suitable for a wide range of electronic devices, from consumer electronics to industrial machinery.

Applications of Skived Heatsinks

Skived heatsinks are used in a variety of sectors where effective thermal management is essential. Some common applications include:

-

LED Lighting Systems: High-powered LEDs generate significant heat, and skived heatsinks help maintain optimal operating temperatures, extending the life of the components.

-

Power Electronics: Inverters, converters, and motor drives rely on efficient heat dissipation to function correctly. Skived heatsinks are ideal for these applications due to their high thermal performance.

-

Telecommunications: Routers, servers, and network switches require constant cooling. Skived heatsinks provide reliable thermal management in these compact, high-performance systems.

-

Automotive Electronics: With the rise of electric vehicles and advanced driver-assistance systems (ADAS), the demand for efficient cooling solutions like skived heatsinks continues to grow.

-

Computing Equipment: CPUs, GPUs, and other components in computers and servers benefit from the enhanced thermal performance of skived heatsinks.

Skived Heatsinks vs. Other Types

It’s helpful to compare skived heatsinks with other common types such as extruded, stamped, or bonded heatsinks:

-

Extruded Heatsinks: These are made by forcing metal through a die to create fins. While cost-effective, they offer lower fin density and less design flexibility.

-

Bonded Heatsinks: These are assembled from separate components, often using adhesives or solder. While they can have high fin density, the thermal conductivity between parts is typically lower.

-

Stamped Heatsinks: These are economical and easy to produce but are limited in thermal performance and fin complexity.

In contrast, skived heatsinks provide the perfect balance of high fin density, excellent thermal contact, and design versatility, making them superior in many high-performance applications.

Factors to Consider When Choosing a Skived Heatsink

When selecting a skived heatsink for your application, several factors should be considered:

-

Thermal Requirements: Analyze the heat output of your components to determine the necessary thermal resistance.

-

Material Selection: Choose between aluminum for cost-effectiveness or copper for maximum thermal conductivity.

-

Fin Design: Consider fin height, spacing, and orientation based on the airflow characteristics of your system.

-

Size Constraints: Ensure the heatsink fits within the physical limits of your design without compromising performance.

-

Mounting Options: Check compatibility with existing mounting systems or determine whether custom solutions are needed.

Conclusion

The skived heatsink is a technologically advanced solution that delivers exceptional thermal management for a wide array of applications. Its unique manufacturing process offers superior performance, high fin density, and excellent thermal conductivity, making it a preferred choice for engineers and designers facing demanding cooling challenges.

As electronic devices continue to evolve, the importance of efficient heat dissipation will only increase. By incorporating skived heatsinks into your thermal management strategy, you ensure that your systems operate reliably, efficiently, and safely under all conditions.