Automation quality control is at the heart of delivering reliable, efficient, and precise processes in modern industries. Whether in manufacturing, logistics, or software development, the ability to consistently produce high-quality results hinges on employing robust automation quality control measures. But what exactly is it, and why is it indispensable for businesses aiming for excellence? Let's explore this concept in detail and how it can transform operations across various sectors.

What Is Automation Quality Control?

Automation quality control combines the principles of quality assurance with cutting-edge automation technology. It ensures that every stage of a process meets set quality standards through automated systems. These systems analyze data, identify anomalies, and make adjustments to maintain consistent outcomes without human intervention.

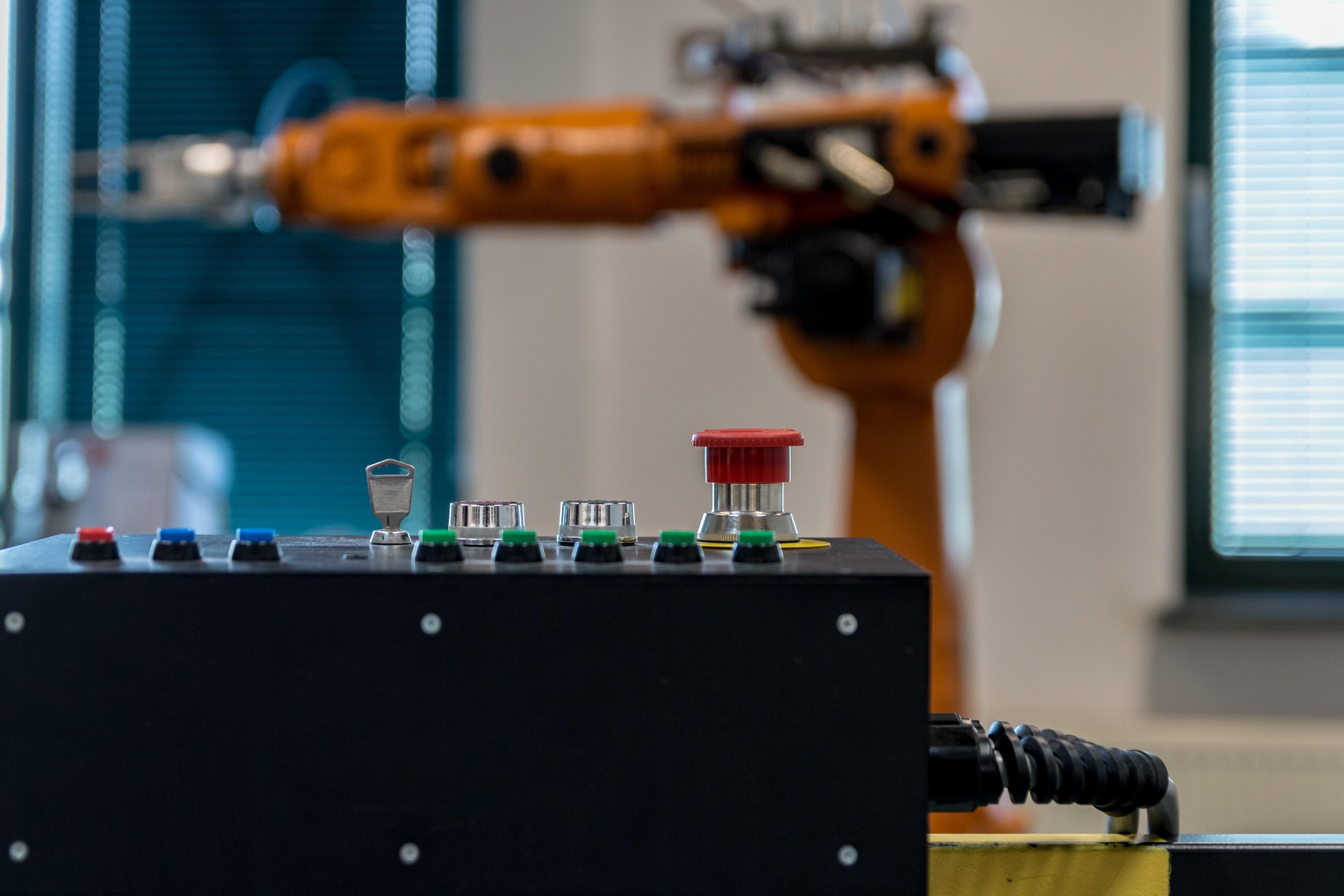

For example, in a manufacturing plant, automated quality control might involve scanning products for defects using sensors and cameras. Similarly, in software development, automated testing tools can check code for performance issues, bugs, or security vulnerabilities.

The integration of automation technology reduces human error, enhances precision, and improves overall efficiency. Companies like Xtreme Automation LLC specialize in providing scalable and high-performance automation solutions tailored to industry needs.

Why Automation Quality Control Matters

1. Consistency Across Operations

Human-centric processes often lead to variability, which can compromise product or service quality. Automation quality control eliminates this concern by ensuring that every phase of the process adheres to defined accuracy levels.

For instance, in industries like automotive production, automated systems can measure components within micrometer tolerances. This ensures a consistent output, reducing customer complaints and maintaining brand credibility.

2. Time and Cost Efficiency

Manual inspections and quality control assessments can be time-consuming and resource-intensive. Automation streamlines these tasks, enabling real-time monitoring and decision-making.

For example, automated systems may identify defective items on a production line instantaneously, removing the need for time-wasting manual inspections. This kind of efficiency allows companies to reduce downtime and optimize resources, ultimately saving costs.

3. Enhanced Data Utilization

Automation quality control leverages data analytics to identify trends, predict potential flaws, and optimize production strategies. Advanced systems generate reports that provide insights into process performance, enabling companies to make data-driven decisions.

For industries like aerospace or medical device manufacturing, where precision is critical, the ability to track and analyze extensive data provides a significant competitive advantage.

Key Features of an Effective Automation Quality Control System

1. Real-Time Monitoring and Feedback

Effective systems operate in real time, detecting inconsistencies and addressing them immediately to prevent defective outputs.

2. AI and Machine Learning Integration

Modern automated control systems use AI and machine learning algorithms to predict issues before they occur. These technologies can build models from historical data to improve processes continuously.

3. Scalability

Automation solutions must be adaptable to various scales, ensuring they cater to small, medium, and large enterprises.

4. User-Friendly Interfaces

A user-friendly interface allows staff to monitor automated systems and interpret data with minimal training.

For businesses considering advanced solutions, Xtreme Automation LLC provides customized automation quality control systems that incorporate these benefits to ensure seamless integration into existing workflows.

Examples of Automation Quality Control in Practice

Manufacturing

Manufacturing plants rely heavily on automation quality control to inspect millions of parts daily. For instance, computer vision systems can scan and identify defects in products like smartphones or automotive components. These systems ensure that only flawless products reach the end user.

Food and Beverage Industry

Automation ensures food processing and packaging meet health, safety, and quality regulations. Scanners, sensors, and AI-driven systems detect contaminants, weight discrepancies, or label errors on the production line.

Software Development

Automated testing tools ensure the quality of software applications by simulating various usage scenarios. These tools detect bugs early in the development phase, reducing costs and enhancing user satisfaction.

Challenges Facing Automation Quality Control

While automation quality control offers numerous advantages, challenges remain. Initial implementation costs can be high, especially for smaller businesses. Additionally, building an entirely automated system often involves integrating new technologies with legacy systems, which can be complex.

However, these challenges pale in comparison to the long-term benefits of streamlined operations, enhanced product quality, and strengthened customer trust.

How to Get Started with Automation Quality Control

If you're considering implementing automation quality control in your business, start by evaluating your current processes. Identify areas where automation could enhance efficiency or prevent defects. Next, partner with an experienced provider like Xtreme Automation LLC, which can design a solution tailored to your unique needs.

The key to successful automation lies in proper planning and gradual implementation. Begin with smaller, well-defined processes before scaling up to more complex systems.

Unlock the Future of Quality Control

Automation quality control is revolutionizing industries by removing inefficiencies, improving consistency, and leveraging data to optimize results. Whether you're in manufacturing, software, or another field, adopting automation can take your operations to the next level.

Collaborate with trusted partners like Xtreme Automation LLC to create intelligent systems that save time, minimize errors, and enhance processes. The future of quality control is automated, and investing today ensures your success tomorrow.