Automation enclosures play a critical role in protecting and organizing the high-tech equipment that drives industrial processes. From housing sensitive electronics to ensuring secure operations in harsh environments, automation enclosures are a crucial part of many industries' infrastructure. Whether you're looking to safeguard your equipment or improve operational efficiency, understanding the importance and benefits of these enclosures can help you make smarter decisions.

What Are Automation Enclosures?

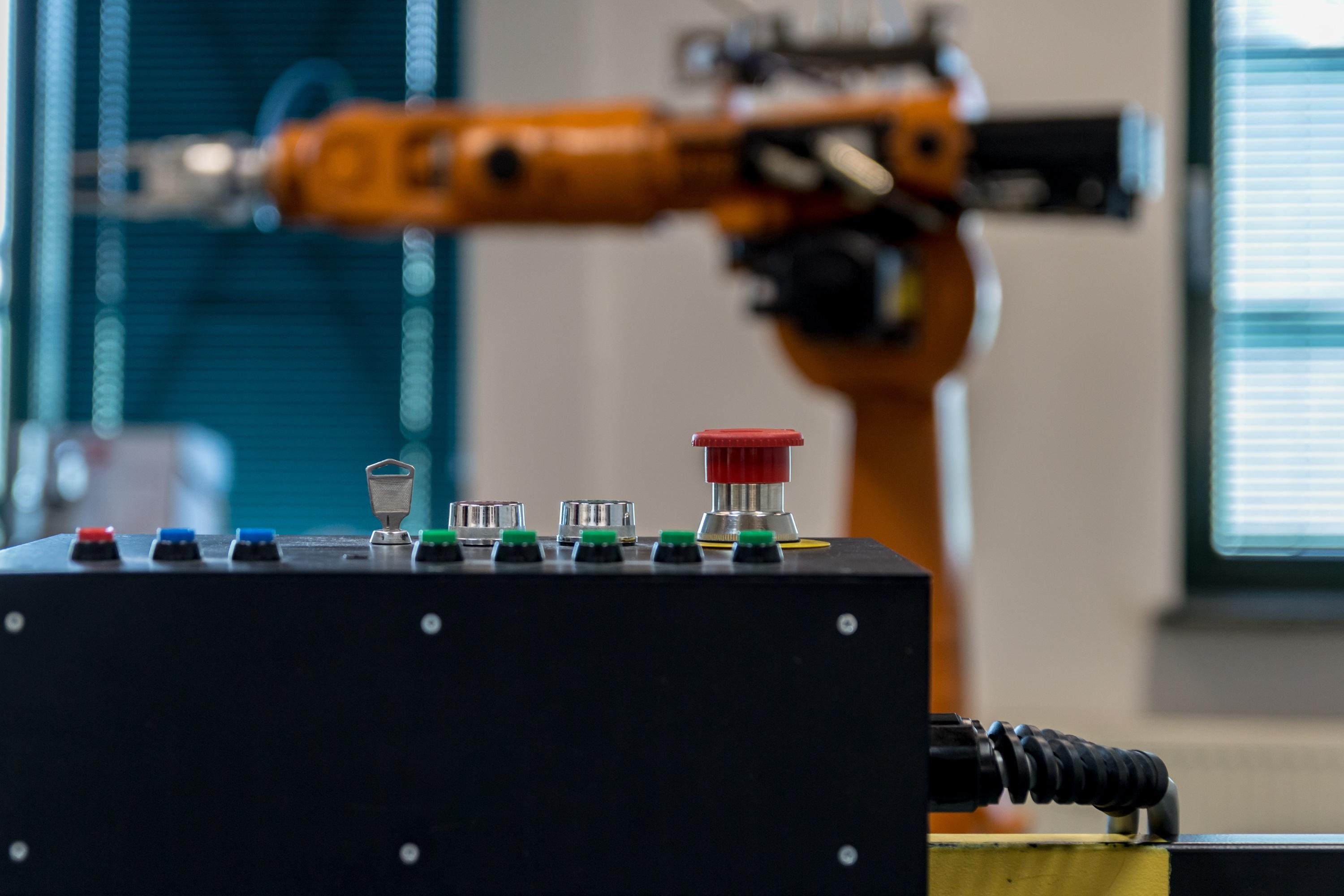

Automation enclosures are protective casings designed to house industrial automation equipment, such as control panels, PLCs (Programmable Logic Controllers), sensors, and relays. These enclosures shield the internal components from risks like dust, moisture, extreme temperatures, and accidental impacts. They are commonly used across industries like manufacturing, energy, and telecommunications to ensure that mission-critical systems operate seamlessly.

Key Features of Automation Enclosures

- Durability: These enclosures are commonly constructed from materials such as stainless steel, aluminum, or fiberglass to withstand harsh environments.

- Customizability: Many manufacturers offer custom enclosures tailored to fit specific configurations and requirements.

- Safety: They provide protection from electrical hazards, aiding compliance with workplace safety standards.

- Ease of Integration: Most automation enclosures are designed for seamless integration into existing systems, with features like pre-drilled mounting points and cable entry gaskets.

Why Are Automation Enclosures Important?

The importance of automation enclosures lies in their ability to protect and organize equipment that is vital to industrial automation. Without these enclosures, sensitive components would be exposed to potentially damaging conditions, leading to disruptions in operations and expensive repairs.

Equipment Protection

Sensitive industrial equipment can be damaged by elements like dust, water, and extreme temperatures. Automation enclosures act as a defense barrier, ensuring these components remain safe and functional. This protection enhances the lifespan of the equipment, saving time and costs associated with frequent replacements.

Operational Efficiency

Automation enclosures make maintenance and troubleshooting easier by ensuring that all components are neatly organized in a single space. This reduces downtime during system checks and repairs, enabling smoother operations in time-sensitive environments.

Compliance and Safety

For workplaces, compliance with safety regulations is non-negotiable. Automation enclosures minimize the risk of electrical hazards, protecting workers from accidental contact with live wires. Many are built to meet industry standards, further ensuring regulatory compliance.

For expert solutions on automation enclosures, visit xtremeautomationllc.com.

Industries That Benefit from Automation Enclosures

Automation enclosures are versatile and find applications across various industries. Here are some sectors where they are indispensable:

Manufacturing

Manufacturing environments often deal with dust, vibration, and fluctuating temperatures. Automation enclosures protect equipment like motor starters and control systems, ensuring uninterrupted production processes.

Energy and Utilities

Power plants and renewable energy facilities use automation enclosures to protect sensitive monitoring and grid control systems. These enclosures also help maintain reliability in remote or challenging locations.

Telecommunications

Telecom systems require enclosures to protect network equipment from the elements. Whether it’s outdoor installations or indoor server rooms, these enclosures play a pivotal role in keeping communication systems running efficiently.

Marine and Offshore

Marine applications demand rugged enclosures that can withstand corrosive saltwater environments. Automation enclosures protect navigation, communication, and control systems on ships and offshore platforms.

Choosing the Right Automation Enclosures

Selecting the right automation enclosure depends on several factors, including the intended application, environmental conditions, and the equipment it needs to house. Here are some tips to guide your selection process:

-

Assess the Environment

Determine whether the enclosure will be used indoors or outdoors. Outdoor enclosures must meet weatherproofing standards, while indoor ones might prioritize space efficiency. -

Look for Certifications

Many enclosures come with ratings like NEMA, IP, or UL certifications, indicating their ability to resist environmental factors such as water and dust. -

Consider Material and Design

Evaluate which material is best suited for your needs. Stainless steel is robust and corrosion-resistant, while fiberglass is lightweight and non-conductive. -

Plan for Expansion

While selecting an enclosure, consider future needs. Choosing an enclosure with extra space can accommodate future expansions or upgrades.

For specific guidance and custom recommendations, xtremeautomationllc.com offers tailored solutions to meet your automation enclosure needs.

The Future of Automation Enclosures

With technological advancements, automation enclosures are evolving to incorporate features like IoT-enabled monitoring, modular designs, and improved thermal management. These innovations ensure enclosures remain relevant as industries adopt more complex and interconnected automation systems.

IoT Integration

Modern enclosures now come with IoT capabilities, enabling remote monitoring and real-time data collection. This helps in predictive maintenance, ensuring that potential issues are addressed before they cause significant downtime.

Modular Approach

Modular enclosures offer flexibility, allowing companies to reconfigure the internal layout without needing to purchase a new enclosure. This is particularly useful for industries undergoing rapid technological shifts.

Enhanced Cooling Solutions

To accommodate high-performance components that generate heat, many modern enclosures come with built-in cooling features like fans, heat sinks, or air conditioning units.

Conclusion

Automation enclosures are more than just protective boxes; they are essential components that contribute to the efficiency, safety, and reliability of industrial operations. By investing in high-quality enclosures, businesses can protect their assets, comply with regulations, and prepare for future advancements in automation technology.

When you're ready to find the perfect enclosure for your needs, don't hesitate to explore expert solutions at xtremeautomationllc.com.