Industries across Jacksonville are rapidly adopting VFD PLC control in Jacksonville, Florida to streamline operations and meet growing automation demands. This combination of Variable Frequency Drives (VFDs) and Programmable Logic Controllers (PLCs) offers a dynamic solution that improves energy efficiency, enhances system performance, and supports complex process control. As automation continues to shape the future of manufacturing, HVAC, and municipal systems, VFD PLC integration is proving to be a key investment for businesses seeking long-term success.

Understanding VFD and PLC Integration

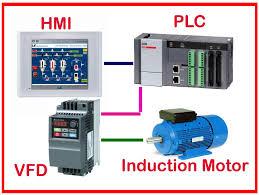

At its core, a VFD controls the speed of electric motors by adjusting the frequency and voltage of the power supplied. PLCs, on the other hand, serve as programmable control units that automate machinery based on custom instructions. When combined, VFDs and PLCs allow for precise motor control, automated decision-making, and reduced wear and tear on equipment.

This integration is especially beneficial in environments where variable motor speeds are essential, such as conveyor belts, pumps, fans, and compressors. Businesses in Jacksonville that implement this technology see reduced mechanical stress, improved energy savings, and greater operational flexibility.

Benefits for Local Industries in Jacksonville

Jacksonville, with its diverse industrial landscape, stands to benefit immensely from advanced VFD PLC solutions. From manufacturing facilities and water treatment plants to packaging centers and distribution warehouses, almost every sector can optimize operations using this technology.

Some of the most impactful benefits include:

-

Energy Efficiency: Motors only run at the speed required, significantly cutting energy consumption.

-

Improved Equipment Lifespan: VFDs provide soft starts and controlled stops, minimizing mechanical shock.

-

Enhanced Safety: PLCs manage safety routines such as emergency stops and system shutdowns.

-

Lower Operational Costs: Reduced downtime and minimal manual intervention lead to cost savings.

Customized Control for Complex Processes

Not every business in Jacksonville has the same needs. That’s why modern VFD PLC systems can be tailored to meet specific operational requirements. Whether it's a packaging line requiring synchronized belt speeds or a pump system needing pressure regulation, the flexibility of programming makes these systems highly adaptive.

Advanced PLCs can incorporate data from sensors and user inputs to make real-time decisions. For example, in an HVAC system, the PLC can read temperature sensors and adjust fan speeds through the VFD to maintain optimal climate control. This ability to automate decision-making not only boosts efficiency but also ensures consistency and reliability.

Supporting Smart Monitoring and Remote Access

One of the most compelling features of today’s VFD PLC systems is their compatibility with remote monitoring tools. Businesses in Jacksonville can manage operations from virtually anywhere using HMI (Human Machine Interface) screens and SCADA (Supervisory Control and Data Acquisition) systems connected to their automation framework.

This connectivity allows for:

-

Real-time system diagnostics

-

Instant alerts and fault detection

-

Remote parameter adjustments

-

Data collection for performance analysis

For companies managing multiple sites, this capability ensures seamless coordination and better decision-making based on live data.

Applications Across Key Sectors

The application of VFD PLC control in Jacksonville, Florida spans numerous industries, with each benefiting in unique ways:

-

Manufacturing: Precision motor control leads to faster, more accurate production with less waste.

-

Water and Wastewater Management: Pumps run at variable speeds based on demand, reducing energy usage.

-

HVAC Systems: Fan and compressor speeds adjust automatically for energy savings and improved comfort.

-

Food and Beverage: Automated control ensures consistency in processes like mixing, bottling, and labeling.

-

Logistics and Packaging: Conveyor systems operate smoothly and safely, improving throughput.

With such wide-ranging applications, more businesses are turning to automation partners to design systems that suit their exact needs.

Middle Use of Keyword and Smart Investment Returns

The decision to invest in VFD PLC control is backed by both technical and economic reasoning. Though the upfront cost of implementing these systems can be higher than traditional motor starters, the long-term savings are substantial.

Lower energy bills, reduced equipment failure, and minimal downtime all contribute to a faster return on investment. Moreover, as energy regulations and automation demands grow more stringent, having a flexible, programmable system puts businesses ahead of the curve.

Choosing the Right Automation Partner

It’s important to work with an automation partner who understands not only the technology but also the local industrial environment. A good provider will evaluate your existing infrastructure, recommend the right VFDs and PLCs, design the system layout, and provide support for installation, programming, and maintenance.

In Jacksonville, where competition and operational efficiency are key, having a reliable partner ensures your systems run smoothly and are equipped for future upgrades, such as IoT integration or machine learning features.

Final Thoughts and Trusted Local Expertise

In summary, VFD PLC control in Jacksonville, Florida provides a robust, intelligent solution for modern industrial automation needs. With benefits like energy savings, precise control, scalability, and remote monitoring, it's no surprise that more local businesses are adopting these advanced systems. As industry demands evolve, investing in flexible, smart automation is more critical than ever. For those seeking expert design and implementation services, Xtreme Automation LLC offers top-tier VFD PLC solutions tailored to meet the exact needs of Jacksonville’s industrial sectors.