As industries across the U.S. move toward smarter, more efficient operations, automation control systems are playing a vital role in reshaping how work is done—especially in innovative towns like Skokie, Illinois. Known for its strong manufacturing base and proximity to the Chicago metro area, Skokie is home to businesses that are leveraging advanced control systems to reduce labor costs, enhance productivity, and improve process accuracy.

Automation control systems form the backbone of modern industrial operations. Whether it’s controlling motors, monitoring temperatures, or coordinating complex sequences in manufacturing, these systems are central to consistent and efficient output. In Skokie, where competition and innovation go hand in hand, adopting automation control is not just an upgrade—it’s a necessity for long-term growth.

What Are Automation Control Systems?

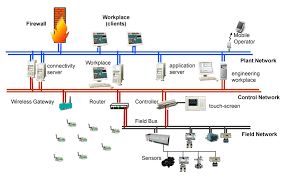

Automation control systems are integrated networks of devices that regulate and manage machines, equipment, and processes in real-time. These systems use a combination of hardware (such as sensors, controllers, and actuators) and software (like SCADA and HMI interfaces) to automatically carry out tasks with minimal human intervention.

Key components of an automation control system include:

-

Programmable Logic Controllers (PLCs) – Industrial computers that manage logic-based control processes.

-

Human Machine Interfaces (HMIs) – Visual platforms that allow operators to monitor and interact with machines.

-

Variable Frequency Drives (VFDs) – Adjust motor speed and torque for energy efficiency and process control.

-

Sensors and Actuators – Input/output devices that detect changes and respond accordingly.

These components are customized and integrated based on the specific needs of each operation, ensuring optimized performance and accuracy.

Why Skokie Businesses Are Turning to Automation Control

The industrial landscape in Skokie is evolving quickly. Manufacturers, food processors, logistics hubs, and other businesses are facing pressure to:

-

Increase throughput

-

Lower labor dependency

-

Meet regulatory compliance

-

Stay cost-competitive

Automation control systems offer a way to address all these goals through one unified approach. Here's why businesses in Skokie are investing in these systems:

1. Enhanced Efficiency

Automation minimizes downtime and boosts output by optimizing machine performance. Processes that once required manual operation are now handled seamlessly by programmable systems.

2. Improved Accuracy and Consistency

Precision is critical in industries like medical device manufacturing and food processing. Control systems ensure every product is made to exact specifications—every time.

3. Real-Time Monitoring and Data Logging

With SCADA and HMI tools, Skokie business owners can view live performance data and receive alerts when conditions change or equipment malfunctions, allowing for proactive maintenance.

4. Energy Savings

Systems like VFDs help manage power usage more effectively by adjusting motor speed according to demand, reducing unnecessary energy consumption.

5. Regulatory Compliance

Automated systems help businesses maintain standards for cleanliness, temperature control, and process safety—critical in FDA- or OSHA-regulated industries.

Industries in Skokie Using Automation Control Systems

Skokie’s diverse industrial base means automation control solutions are being applied across a range of sectors:

Manufacturing

Automation streamlines assembly lines, CNC machining, welding, and testing processes to maintain quality and speed.

Food and Beverage Processing

Temperature monitoring, batch mixing, and packaging operations are automated to meet safety standards and scale production efficiently.

Pharmaceuticals and Life Sciences

Precise control is essential in drug production and lab automation. Systems help monitor environmental conditions and control fluid processes.

Warehousing and Distribution

Material handling systems, barcode scanners, conveyors, and storage systems benefit from real-time automation and smart tracking.

Utilities and Infrastructure

From water treatment plants to public transportation systems, control panels and SCADA systems manage everything from power distribution to HVAC operations.

What to Look for in a Skokie Automation Provider

Not all control system providers are the same.

-

Industry Experience: Make sure the provider has expertise in your sector and understands your workflow.

-

Custom Engineering: Choose companies that offer tailored solutions instead of pre-packaged systems.

-

Scalability: Systems should be able to grow with your business or adapt to new technologies.

-

Local Support and Training: Proximity to your facility ensures quick service response and hands-on support.

-

Proven Tools and Technology: Top providers use components from trusted brands like Allen-Bradley, Siemens, and Schneider Electric.

Automation Trends Affecting Skokie Businesses

As automation technology continues to advance, Skokie-based companies can take advantage of trends such as:

-

Remote Access and Cloud Integration

Managers and technicians can access systems remotely for monitoring and updates. -

Green Automation

Systems designed to reduce energy waste and support sustainability initiatives. -

Machine Learning and AI Integration

Intelligent systems that learn and adapt over time for even greater optimization.

The Future of Automation in Skokie

With ongoing investments in infrastructure and technology, Skokie is poised to become a leader in smart manufacturing and automated processes. The push for efficiency and modernization means automation control systems will continue to play a central role in how local businesses grow and compete.

By implementing automation now, businesses in Skokie can take advantage of today’s technology while laying the foundation for tomorrow’s innovation.

Work with a Trusted Partner for Automation in Skokie

If your business in Skokie is exploring the benefits of automation control systems, Xtreme Automation LLC offers expert engineering, system design, and integration services tailored to your specific needs. With a focus on reliability, performance, and long-term support, they help companies in Illinois operate smarter and scale efficiently.