In today’s competitive industrial landscape, facilities in Dekalb, Illinois, are seeking smarter ways to manage energy, reduce equipment wear, and improve overall operational efficiency. One solution that continues to gain traction across industries is variable frequency control—a powerful method of controlling the speed and torque of electric motors based on actual demand.

Whether you're running an HVAC system, conveyor belts, water pumps, or production machinery, integrating variable frequency drives (VFDs) as part of a variable frequency control system can deliver substantial energy savings and process flexibility. In Dekalb, where agriculture, warehousing, education, and manufacturing converge, this technology is becoming an essential part of electrical and mechanical infrastructure.

What is Variable Frequency Control?

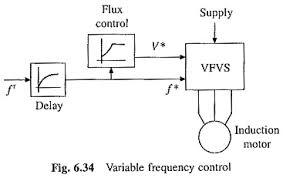

Variable frequency control refers to the use of electronic systems, typically variable frequency drives (VFDs), to regulate the speed and performance of electric motors. VFDs alter the frequency and voltage supplied to an AC motor, allowing it to run at speeds that match the operational requirements instead of full speed all the time.

Key components of a typical variable frequency control setup include:

- Input rectifier

- DC link (capacitors)

- Inverter module

- Microprocessor-based controller

- User interface and communication module

By converting a constant frequency and voltage input into a variable output, VFDs allow real-time control over motor performance—leading to significant efficiency gains.

Why Variable Frequency Control is Essential in Dekalb

Dekalb’s economy is driven by a unique blend of agriculture, logistics, higher education, and small-to-mid-sized manufacturers. Whether it’s powering irrigation systems on the outskirts or managing climate control in educational institutions like Northern Illinois University, energy efficiency is top of mind.

Here’s how variable frequency control makes a difference in Dekalb:

✅ Energy Savings

Running motors at full speed constantly wastes energy. VFDs adjust motor speed based on load demands, cutting energy use by up to 50% in some applications.

✅ Extended Equipment Life

Reduced motor speed means less wear on belts, bearings, and mechanical components—minimizing downtime and maintenance costs.

✅ Improved System Control

VFDs allow soft starts and stops, reducing voltage spikes and mechanical stress. This is critical for sensitive equipment in labs, data centers, and clean manufacturing.

✅ Sustainability and Compliance

Local industries must meet growing environmental regulations. VFDs contribute to greener operations and lower carbon footprints.

Key Applications in Dekalb

Variable frequency control systems are used across multiple sectors in Dekalb. Some prominent applications include:

🏭 Manufacturing & Industrial Plants

Control material handling systems, packaging lines, and processing machinery with dynamic speed control.

🌾 Agriculture & Irrigation

Run irrigation pumps efficiently and avoid surges or sudden stops that could damage pipelines or affect crop watering schedules.

🏫 Education & Institutional Buildings

VFDs in HVAC systems help schools and universities regulate temperature while reducing utility costs.

🚛 Warehousing & Distribution

Conveyor belts, automated storage, and retrieval systems all benefit from variable speed motors to handle different load demands.

How Does Variable Frequency Control Work?

The fundamental principle behind variable frequency control is that motor speed is directly proportional to the frequency of the electrical supply. A VFD adjusts both voltage and frequency, ensuring the motor operates efficiently at any speed.

The three phases of control include:

- Rectification: Converts incoming AC power to DC.

- DC Bus: Filters and stores energy in capacitors.

- Inversion: Converts DC back into a variable frequency AC output, sending it to the motor.

A built-in microcontroller processes sensor feedback and user input to adjust the output in real time. Advanced models even support IoT connectivity, making remote monitoring and diagnostics possible.

Selecting the Right VFD for Your Application

Not all VFDs are created equal. The right system depends on:

- Motor size and type

- Load characteristics (constant torque vs. variable torque)

- Environmental conditions (indoor, outdoor, dust, moisture)

- Communication requirements (Ethernet/IP, Modbus, BACnet)

- Safety standards (UL, CSA, CE)

Businesses in Dekalb should also consider local energy incentives or utility rebates for installing energy-efficient systems, which VFDs often qualify for.

Installation & Integration Considerations

To maximize ROI and ensure safety, VFDs must be properly integrated:

- Shielded cables and EMI filters to reduce electrical noise

- Proper grounding to prevent system faults

- Load balancing and harmonic filtering for large installations

- Use of NEMA-rated enclosures for specific environments

- Coordination with PLC or SCADA systems for process automation

- Hiring an experienced integrator ensures your VFDs are correctly sized, installed, and programmed to suit your application needs.

- Challenges and How to Overcome Them

While VFDs offer many benefits, some challenges include: - Harmonic distortion affecting sensitive electronics

- Voltage drops in long cable runs

- Startup programming complexity

- Training staff to troubleshoot VFDs

These can be addressed through proper engineering design, filtering devices, and working with vendors that offer commissioning support and training services.

Final Thoughts

For businesses and institutions in Dekalb, Illinois, variable frequency control is no longer a luxury—it’s a necessity. As energy prices fluctuate and sustainability becomes a strategic focus, implementing VFDs can transform how your systems operate—boosting efficiency, lowering costs, and extending the life of critical equipment.

If you’re ready to modernize your systems with cutting-edge automation, Xtreme Automation LLC offers custom-engineered variable frequency control solutions designed for your industry’s specific needs.