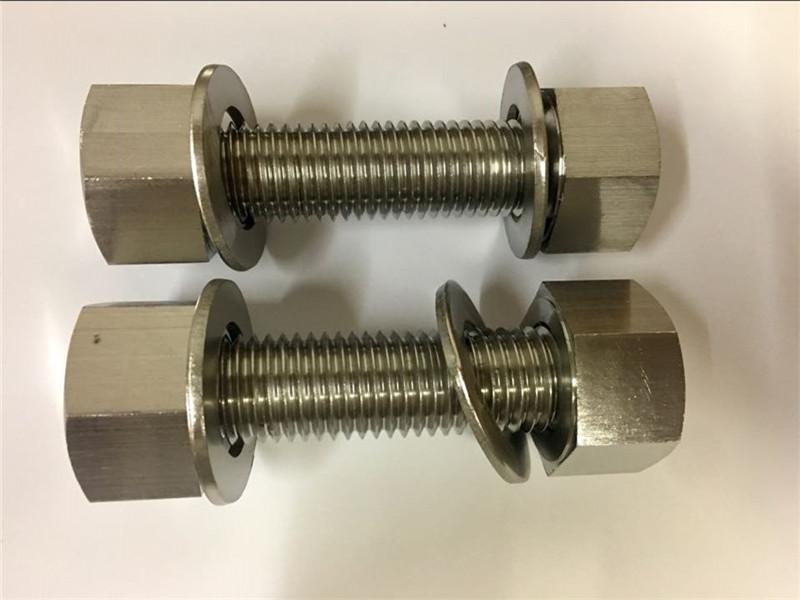

Inconel 600 stud bolts are widely used in industries like chemical processing, power generation, and marine applications due to their exceptional resistance to heat, corrosion, and stress. However, to maximize their performance and lifespan, it’s critical to follow proper installation procedures. This blog will guide you through key tips and best practices to ensure safe and effective installation of Inconel 600 stud bolts.

1. Inspect Bolts Before Installation

Before installation, always inspect the Inconel 600 stud bolts for:

-

Surface defects, cracks, or pitting

-

Thread damage or deformation

-

Signs of corrosion or contamination

Using damaged bolts can compromise joint integrity and safety, so replace any defective components before proceeding.

2. Use Proper Tools and Equipment

Use the correct wrenches, torque wrenches, or hydraulic tensioners designed for the specific stud size and application. Avoid using worn-out or mismatched tools that can damage threads or lead to improper tightening.

3. Apply Lubrication

Even though Inconel 600 offers excellent corrosion resistance, it’s recommended to apply an appropriate anti-seize or high-temperature lubricant to the threads and nut-bearing surfaces before installation. This helps:

-

Reduce galling (thread seizing)

-

Achieve accurate torque readings

-

Ensure smooth tightening and easy removal during future maintenance

4. Follow Correct Torque Specifications

Over-tightening or under-tightening can lead to failure or leakage in critical systems. Always:

-

Refer to the manufacturer’s torque chart or the applicable engineering standard (e.g., ASME, ASTM)

-

Use calibrated torque wrenches

-

Tighten in a star or crisscross pattern when working with flange connections to distribute load evenly

5. Maintain Proper Bolt Alignment

Misalignment can lead to uneven load distribution and premature failure. Make sure the stud bolts are correctly aligned with the mating components and are seated evenly before tightening.

6. Perform Gradual Tightening

When tightening multiple stud bolts, especially on flanges or pressure vessels:

-

Start by tightening all bolts to 30% of the final torque

-

Increase to 60% in the second pass

-

Reach 100% of the final torque in the third pass

-

Perform a final check to ensure uniform tension across all bolts

7. Conduct Post-Installation Inspection

After installation:

-

Check for proper engagement of threads (minimum of one full thread beyond the nut)

-

Inspect torque values

-

Verify gasket or flange alignment if applicable

Regular inspection after commissioning can help detect early signs of loosening or wear.

Conclusion

Proper installation of Inconel 600 stud bolts is essential to ensuring the safety, performance, and longevity of industrial systems. By following these best practices — from inspection and lubrication to correct torque application and post-installation checks — you can prevent common issues like thread galling, leakage, and premature failure. Well-installed Inconel 600 fasteners will deliver reliable service even in the harshest environments.